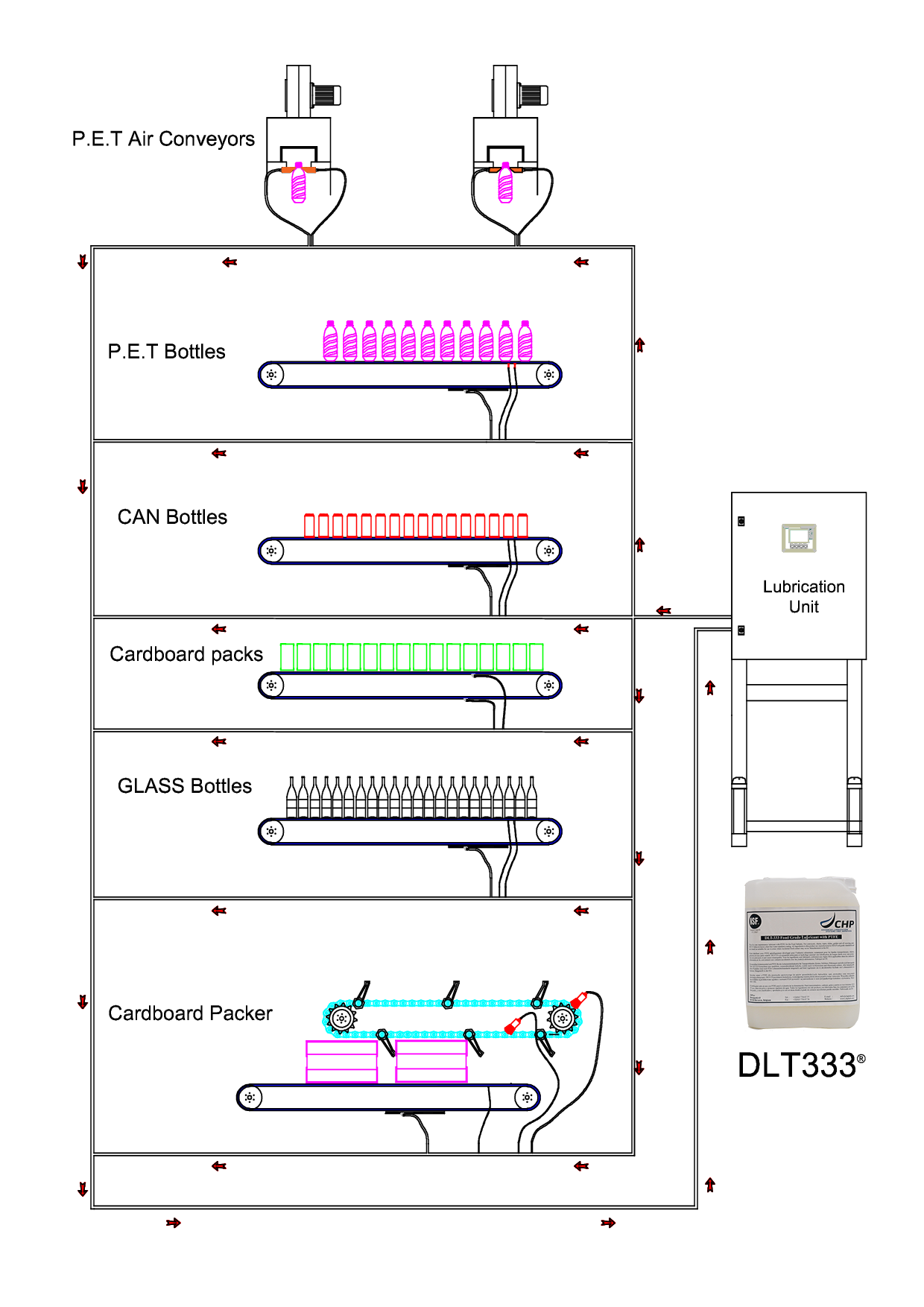

PRAUCS, in collaboration with CHPnv (a Belgian and global brand offering state-of-the-art lubrication and cleaning solutions), provides a PTFE hygienic lubrication solution for contact surfaces in slat chains and air conveyors using lubricant DLT-333®, with food grade components that are recommended for Cardboard, PET, CSD – Aluminum Cans and Glass lines.

Benefits

- Water-free/Dry Lubrication

- Wear strip & Chain Protection

- Low Lubrication Cost

- Low Friction

- Low Consumption

- Water & Energy Saving

The total investment over five years will save you more than 30% of your current solutions.

Praucs offers:

– A turnkey solution, from study and design to implementation and commissioning

– Training and scheduled inspections

– Different payment options, flexibility, and the possibility to gain the solution without a CAPEX

- MicroDry® AIR is integrated in the neck guiding strip of the air conveyors

- No brushes, no spray nozzles are needed

- Longer lifespan for neck guides and strips

- bottle jam reduction of 80% to even 100%

- Filling line efficiency improvement

- Low running cost

- Low consumption of coating agent

- Air filters and Energy saving

- Top and bottom lubrication of each chain

- No brushes, no spray nozzles are needed

- Different zones of lubrication: from blow molder to after the packer

- Smooth run- low friction

- Higher line efficiency

- Low running cost

- Low consumption of coating agent

- Water and energy saving

- lubrication between chain and package, chain and wear strip.

- lubrication of roller chains

- Fully automatic distribution serving multiple lines

- The dosing is independent and precise for each nozzle

- High quality material ,5-year warranty

- Built in Lubricant tank

- Controlled by Siemens S7 – HMI

- High quality powerful pump that can feed many lubrication points at the same time

- Very tiny foot print and can be installed anywhere in the factory

- A patented technology

- Water-free and Chemical-free

- Food-grade Lubricant

- Creates a full and thin lubrication layer between contact surfaces

- Fully stable, can handle high pressure

- Minimal friction: between 0.06 and 0.08

- Water and Dust repellent which keeps the conveyor clean and dry

- Ideal for lubrication between chain and package, chain and wear strip, and also for roller chains and air conveyors

- Recommended by international OEMs like Tetrapack, SIG Combiblock, Sidel, Krones, Mariani, Technica and many others