Do you know the value of the transporter?

Line efficiency is a term that every manufacturer knows and understands that the more it increases, the more profitable his business becomes.

The importance of conveyors in the production line

Many factors affect the efficiency of the production line. The question is: have you ever thought about the effect of conveyors on the efficiency of the bottling or canning line?

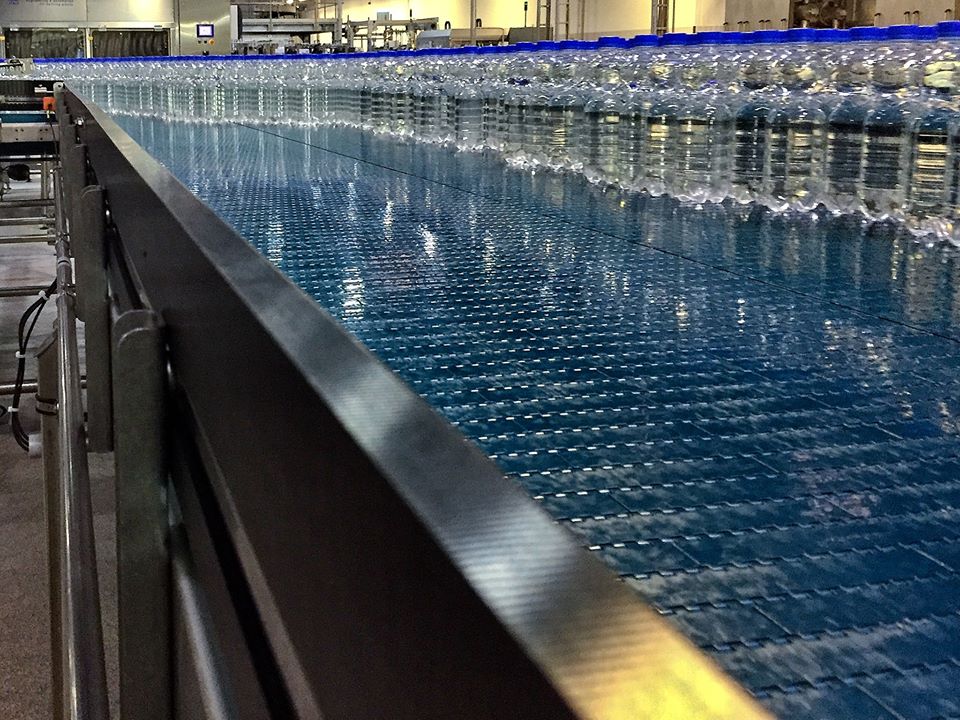

We all know that the conveyor belts are the links between machines of a line. From another perspective, this connection is the backbone of the line, which is responsible for an intelligent and continuous supply of these machines.

The effect of the conveyor belt on bottling or canning lines

Some machines accept single products, some accept mass products, the conveyors will feed and unload them, communicate with each of them to slow down or increase the speed of supply and in case of machine stop, it will give this machine some recovery time by accumulating products before it asks all the other machines to stop and wait for their team member to come back into the game.

- The smoother the supply (or in other terms the absence of vibrations, the absence of pressure between products, and the higher stability of the product), the smoother the delivery and discharge will be for single and mass inputs/outputs.

- The smarter the supply (or in other terms the ability to synchronize electrically and mechanically with the machine’s speeds), the faster the entire line will return to its high speed.

- The more reliable the conveyor is (or in other terms the less break down it receives from the broken chain to the broken sprockets, to the broken motor, to the worn wear strips), the more production time is gained.

So the conveyor belts are the backbone of the line and one of the main players in the efficiency of the line!

Conveyor Care – What is the best solution?

Now here’s what is still missing: conveyors are also machines, they have needs and require care. Of course, you want to choose the best solution available for the backbone machines to meet their needs and care, with the lowest operating cost possible.

For care, we recommend preventive maintenance, as well as lubrication of the wear strips and automatic cleaning.

For the best transport performance, choose the supplier that can precisely control the friction between the chain and the product with long-lasting high-quality lubrication material that is not affected by water or spillage, in other words, you have to look for full layer lubrication that is automatically renewed to guarantee a smooth, intelligent and reliable conveyor that will be the backbone of the line’s efficiency.

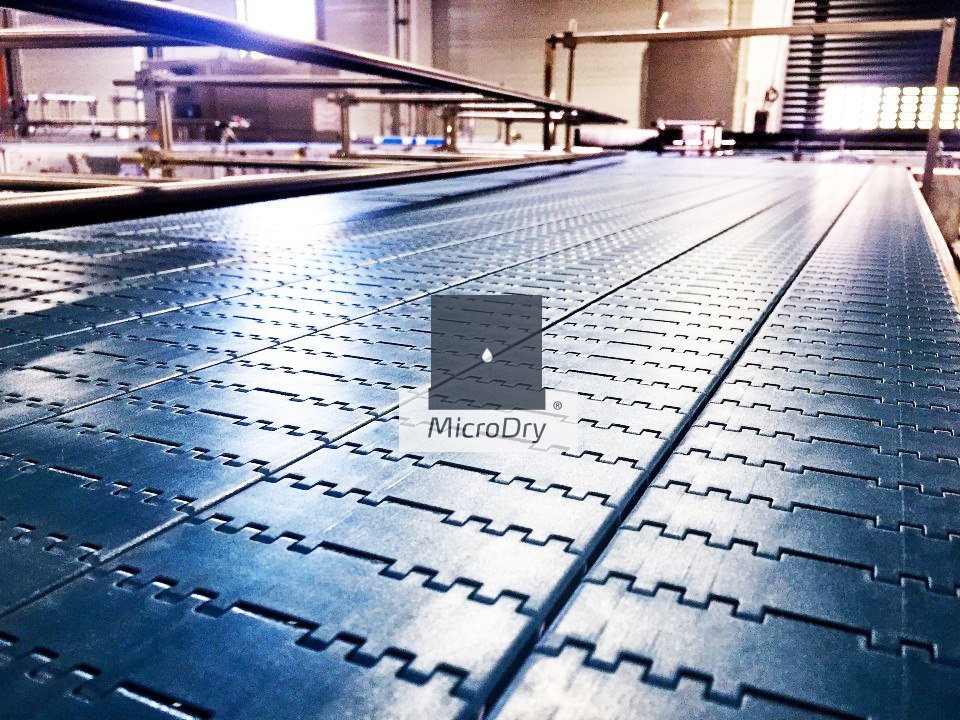

MicroDry®lubrication system

The MicroDry® lubrication system is water-repellent and dirt-resistant. It is a patented technology for slat and air conveyors used for PET bottles, glass bottles, cans, cardboard packs, jars, etc.

MicroDry® is a dry lubrication solution that can manage a complete filling line and offers more valuable advantages from other lubrication methods: greater line efficiency and low running costs.

PRAUCS