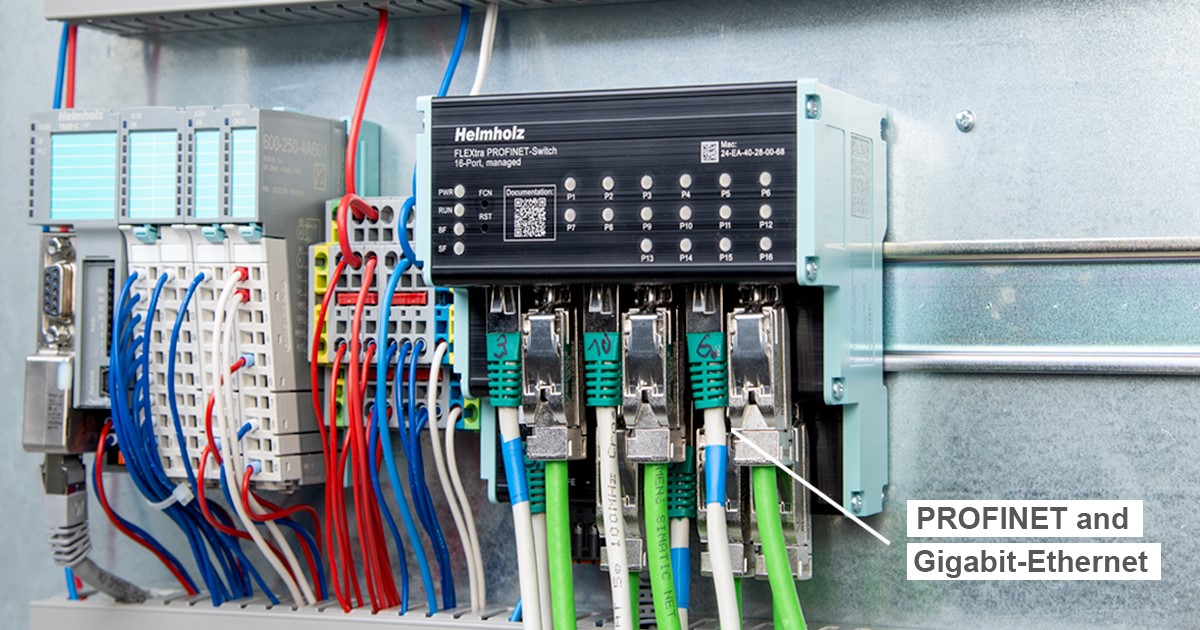

Featuring a totally new, “tiered” design, the PROFINET Switch will enable cable entry straight from the bottom, giving a better and easier bending radius of the cables.

The FLEXtra PROFINET switch connects the control world with PROFINET according to Conformance Class B and the IT world with up to 1GBit Ethernet. With the FLEXtra PROFINET switch, PROFINET components with 100 Mbps as well as Ethernet subscribers with up to 1000 Mbps can be networked.

This enables communication from the control level and the machine in one switch. The PROFINET prioritization of the machine level is always guaranteed.

One of the most important functions of a PROFINET switch is the prioritization of PROFINET telegram traffic in the machine network. The managed switch can distinguish whether the telegram is a web request, an FTP file transfer, a media stream, or a PROFINET telegram. If the transmission load is high, the important telegrams can thus be prioritized to prevent telegram loss. Using a GSDML file, you can integrate the switch into your automation environment as usual.

The supported PROFINET protocols, such as LLDP, DCP, or diagnostic alarms, can be easily parameterized and managed.

The practical design with the intelligent arrangement of the Ethernet sockets saves space in the control cabinet.

The always clearly visible status LEDs on the top of the FLEXtra PROFInet Switch allow easy diagnostics even with full cabling.

Technical advantages when using a PROFINET-Switch

- Prioritizing of PROFINET frames

- Assignment of a configuration via the device name

- Neighborhood detection

- Device exchange without programming device

- Ring redundancy

- Each port can be activated or deactivated

- Diagnostic messages for network problems

- Identification and maintenance data