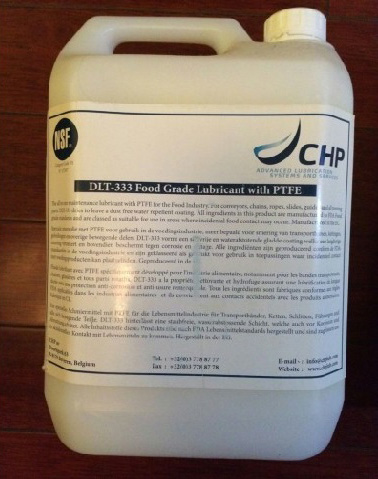

PRAUCS in collaboration with CHPnv provides a lubrication solution for top and bottom surfaces of slat chain with PTFE hygienic lubricant “DLT-333”, through hydraulic food grade components, that are recommended for Cardboard, PET, CSD and Glass lines.

Stainless steel or Plastic Chain top and bottom surfaces are independently lubricated via adjustable injection units and software using HMI for programming and setting parameters.

Depending on chain counting, each conveyor is equipped by the required lubrication injections which are tested and assembled in the factory in Belgium before installation.

The hydraulic circuit uses high pressure pipes in a circular topology that allows the connection to up to 8 lines on a single control unit.

Control unit provides precisely the needed lubricant quantity to every injection unit allowing full friction control all over the production line and through different production conditions.